Axial Fan VS Centrifugal Fan: All You Need To Know

Axial and centrifugal fans seem to be two sides of the same coin. Axial fans can move a high volume of air even in low-pressure contexts, whilst centrifugal fans deal with high-pressure airflow.

In this article, we will make a comparison between axial and centrifugal fans to underline their advantages and disadvantages. We will also delve into their respective working principles to provide you with all the information you need to choose the best ventilation system for your activity.

On this page, we will discuss:

The Main Differences Between An Axial Fan And A Centrifugal Fan

Understanding the main differences between axial and centrifugal fans is crucial to grasp how air moves through blades. Axial fans use a skewed blade design to capture the air and direct it in a parallel direction to the shaft. On the other hand, centrifugal fans expel air with a 90-degree angle, which is beneficial for moving air against greater resistance.

As already mentioned, another relevant difference resides in noise levels, as axial fans are generally noisier than centrifugal fans, depending on the dimensions and the type of applications.

Furthermore, when considering the installation process, axial fans tend to be smaller, simpler, and lighter than centrifugal fans that feature a heavier, more complex structure.

Would you like to know more about CBI Group’s centrifugal and axial fans?

Contact us for more information!

A Comparison Between Axial Fans And Centrifugal Fans

When it comes to ventilation systems, industries and commercial activities face a critical choice between axial and centrifugal fans. Let’s have a look at the main advantages of both these solutions.

All The Advantages Of Axial Fans

The definition of axial fans, also known as propeller fans, describes them as an ideal solution for warehouses and commercial buildings. They are suitable for applications, both in small and large environments, where high airflow is required. These fans are favoured for general cooling and ventilation purposes due to their energy efficiency.

Another advantage that should not be overlooked is their maintenance. As a matter of fact, their simple design facilitates cleaning on a regular basis, preserving the mechanism of the axial fan over the years.

However, axial fans tend to produce more noise than centrifugal fans. For this reason, they are not located in noise-sensitive areas that can be affected by this technical feature.

Pros And Cons Of Centrifugal Fans

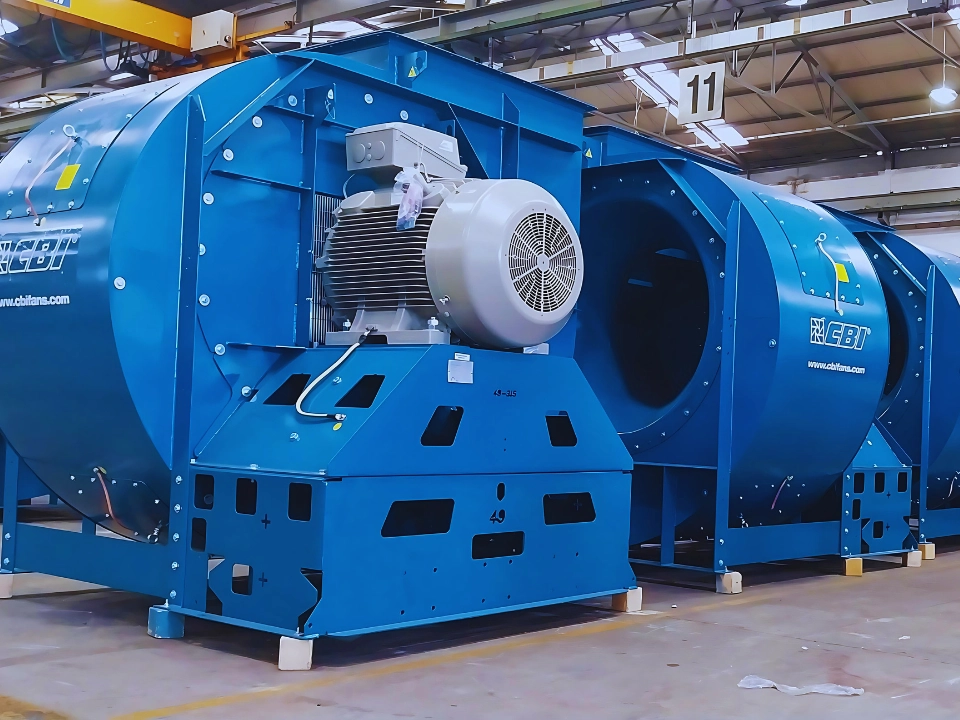

Centrifugal fans, also known as blowers, immediately differ from axial fans as they are more suitable for scenarios where air needs to be displaced under high-pressure. In this case, this solution is more appropriate in contexts such as air filtration systems, cooling towers, and several industrial processes.

Notably versatile, they can manage a wide range of airflow and pressure levels. Due to their robust structure, centrifugal fans can perform well even in environments with harsh conditions.

Another difference between blowers and axial fans is that they can operate more quietly. For this reason, this is a preferred solution in noise-sensitive working scenarios.

Nevertheless, centrifugal fans have their downsides, such as a complex design and, consequently, more maintenance operations.

There are many centrifugal fan models, including airfoil, backward-curved, forward-curved, and radial blades, each standing apart for the angle of their blades.

About The Axial Fan VS Centrifugal Fan’s Working Principle

Gaining an in-depth knowledge of the working principles of both axial and centrifugal fans is crucial for insights about their mechanism, how air interacts with blades, and which model is most suitable for specific applications and environments.

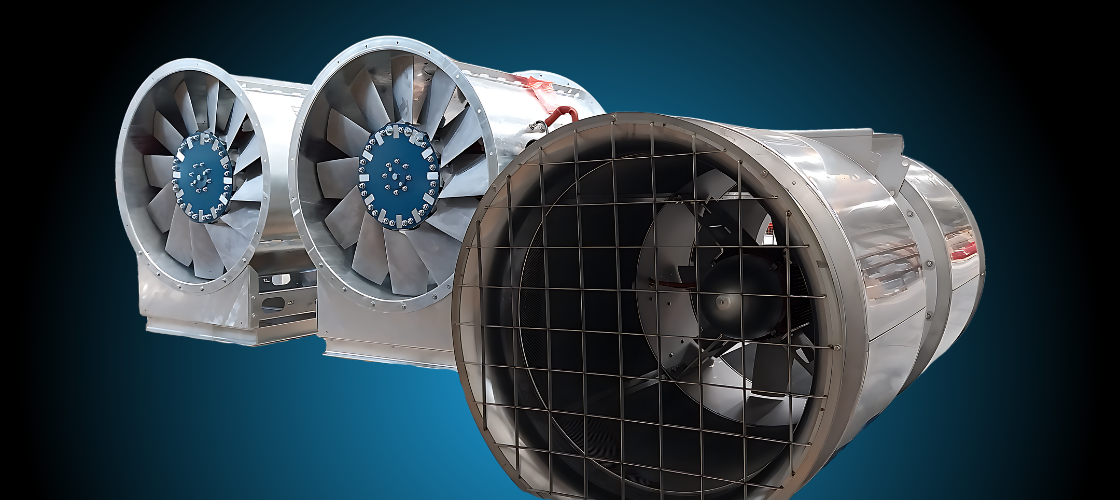

Axial Fans

In this case, air is drawn in line with the shaft and then propelled outwards in a parallel direction. This operating mechanism is particularly effective in situations which require to displace large volumes of air, whilst maintaining a compact structure space-wise. They also deliver a high flow rate at a relatively low pressure.

Centrifugal Fans

Conversely, centrifugal fans expel air at a 90-degree angle to the intake direction. The air movement is accomplished through centrifugal force generated by rotating impellers, displacing air radially. This design facilitates the creation of a higher pressure airflow, with a significant effect over operations inside filtration, drying, or HVAC systems.

Naturally, it is fundamental to opt for a fan aligned with the type of application based on the volume of air, pressure rate, and environmental conditions.

Which Is The Best Fan For Your Business?

The decision-making process is never linear, especially when the choice comes down to axial fan vs centrifugal fan.

CBI Group’s centrifugal fans have been designed to be durable thanks to high-quality materials that makes them corrosion-resistant even in harsh industrial environments. With this solution, ventilation will be professional, consistent and reliable over time.

Conversely, axial fans by CBI Group combine versatility and efficiency in the most diverse scenarios. They are thermal-resistant (up to 400°C) and can be installed even in explosive environments.

Both axial and centrifugal fans by CBI Group are compliant with ATEX regulations.

Would you like to know more about our centrifugal and axial fans?

Contact us for more information!