Polypropylene and Plastic Industrial Fans: Durable Solutions for Corrosive Environments

In industrial environments where exposure to chemicals, humidity, and aggressive agents is frequent, selecting the right fan or blower system is crucial. Traditional metal fans may corrode over time, leading to reduced efficiency, higher maintenance costs, and premature failure.

This is where polypropylene and plastic industrial fans offer an optimal solution. Their high chemical resistance, lightweight design, and durability make them ideal for applications in chemical plants, laboratories, and industrial processes requiring corrosion-resistant ventilation.

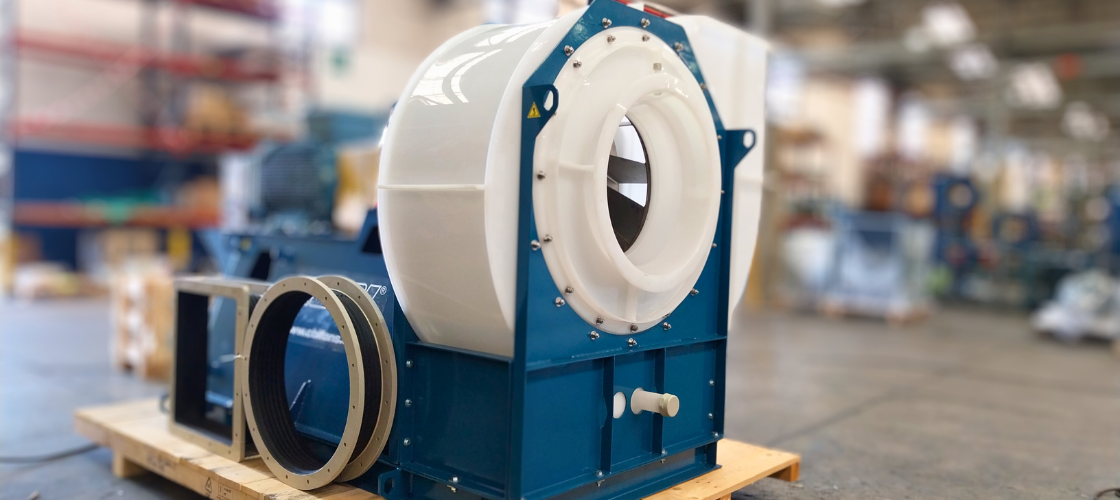

CBI, a leader in industrial ventilation, offers a range of polypropylene and plastic centrifugal fans specifically designed for these challenging conditions.

Insights in this article:

Overview of CBI's Industrial Centrifugal Fans with Polypropylene and Plastic Executions

CBI Group, with over 60 years of experience in industrial ventilation, manufactures high-performance fans that meet strict efficiency and durability standards. The company provides a comprehensive range of centrifugal fans, including models constructed in polypropylene and other high-performance plastics.

ChT Series

-

Constructed with polypropylene to resist highly corrosive substances.

-

Available in multiple sizes and configurations for customized air management solutions.

ChT Series

Ch Series

-

Built for industrial applications requiring high resistance to chemical exposure.

-

Features airfoil or backwardly inclined blades, optimising aerodynamic performance.

-

Can handle flow rates up to 450,000 m³/h and temperatures up to 300°C.

Ch Series

K Series

-

Offers a balance of high performance and corrosion resistance.

-

Designed for environments requiring both chemical resistance and strong airflow capacity.

-

Available in 18 sizes, with impeller diameters up to 2,200 mm.

K Series

CBI’s polypropylene industrial fans ensure long-lasting performance while reducing maintenance costs and downtime.

Request a personalised quote or ask for information

Advantages of Polypropylene in Industrial Fans

Why choose polypropylene for industrial fans? This thermoplastic material offers several advantages over traditional metallic constructions:

-

Superior Chemical Resistance – Unaffected by acids, bases, and aggressive industrial chemicals.

-

Corrosion-Free Performance – Unlike metal fans, polypropylene fans do not rust or degrade in humid environments.

-

Lightweight Yet Sturdy – Easier to install and maintain without compromising on durability.

-

Energy Efficiency – Lower weight and smooth surfaces reduce energy consumption in ventilation systems.

-

Cost-Effective Maintenance – Extended lifespan with minimal wear and tear.

These characteristics make polypropylene fans ideal for sectors where air contamination, corrosive gases, and chemical exposure are concerns.

Applications in Chemical and Laboratory Settings

CBI’s polypropylene and plastic industrial fans are widely used in:

-

Chemical Processing Plants – Handling corrosive vapours and maintaining air purity.

-

Pharmaceutical and Biotechnology Labs – Ensuring sterile, contamination-free airflow.

-

Wastewater Treatment Facilities – Preventing fan degradation from exposure to harsh chemicals.

-

Food and Beverage Industry – Where sanitation and chemical resistance are essential.

-

Fume Extraction Systems – Safely ventilating hazardous gases and chemical fumes.

By selecting the right industrial fan, businesses can enhance workplace safety, optimise airflow efficiency, and reduce equipment failure risks.

Maintenance and Longevity of Plastic Fans

CBI’s polypropylene fans are engineered for long-term reliability with minimal maintenance. To ensure optimal performance:

-

Regular Inspections – Check for dust accumulation and ensure smooth motor operation.

-

Periodic Cleaning – Remove chemical residues to maintain airflow efficiency.

-

Component Checks – Inspect impellers and casings for wear, replacing parts when necessary.

-

Proper Installation – Ensuring correct placement optimises durability and efficiency.

To further extend the lifespan of its fans, CBI offers a preventive maintenance contract, providing regular servicing, predictive diagnostics, and timely interventions to prevent unexpected failures and optimise efficiency.

Which Is The Best Fan For Your Business?

The decision-making process is never linear, especially when the choice comes down to axial fan vs centrifugal fan.

CBI Group’s centrifugal fans have been designed to be durable thanks to high-quality materials that makes them corrosion-resistant even in harsh industrial environments. With this solution, ventilation will be professional, consistent and reliable over time.

Conversely, axial fans by CBI Group combine versatility and efficiency in the most diverse scenarios. They are thermal-resistant (up to 400°C) and can be installed even in explosive environments.

Both axial and centrifugal fans by CBI Group are compliant with ATEX regulations.

Would you like to know more about our centrifugal and axial fans?

Request a personalised quote or ask for information