Quiet Industrial Fans: The Importance of Insulation in Noise Reduction

Noise pollution in industrial environments can significantly impact productivity and pose health risks to workers. Selecting the right quiet industrial fan, equipped with proper insulation, is crucial to ensuring a safe and efficient workspace. This article explores how insulated axial and centrifugal fans can minimize noise emissions while maintaining high performance. We will also introduce CBI Group’s industrial fans, designed with advanced noise-reduction solutions.

Highlights:

The Role of Insulation in Quiet Industrial Fans

Industrial fans generate noise primarily due to airflow turbulence, vibrations, and mechanical components. Insulation plays a vital role in mitigating these factors by:

-

Absorbing sound waves – High-density materials, such as rock wool, help dampen noise.

-

Reducing vibrations – Proper casing insulation prevents structural resonance.

-

Enhancing airflow efficiency – Optimized internal linings reduce turbulence, leading to quieter operation.

Insulated fans are especially beneficial in industries requiring low noise levels, such as HVAC systems, clean rooms, and manufacturing plants with strict sound regulations.

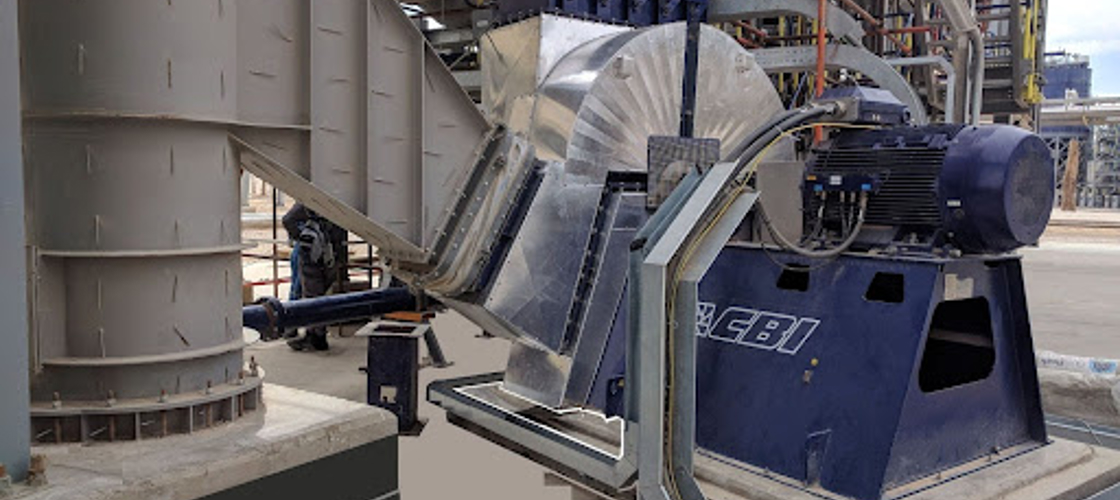

Spotlight on CBI’s Low-Noise Industrial Axial and Centrifugal Fans

CBI Group, a leader in industrial ventilation, offers a range of quiet axial and centrifugal fans designed for optimal performance and noise reduction. Below are some of their standout models:

Ch Series – High-Performance, Low-Noise Centrifugal Fans

-

Impeller Sizes: up to 2,450 mm

-

Maximum Airflow: 450,000 m³/h

-

Maximum Pressure: 6,500 Pa

-

Temperature Resistance: up to 300°C

Discover more

K Series – Energy-Efficient Quiet Centrifugal Fan

-

Impeller Sizes: up to 2,200 mm

-

Maximum Airflow: 370,000 m³/h

-

Maximum Pressure: 9,000 Pa

-

Temperature Resistance: up to 300°C

Discover more

Z Series – Compact and Silent Centrifugal Fan

-

Impeller Sizes: up to 2.200 mm

-

Maximum Airflow: 400,000 m³/h

-

Maximum Pressure: 9,500 Pa

-

Temperature Resistance: up to 300°C

Discover more

X Series – Powerful Yet Quiet High-Performance Fan

-

Impeller Sizes: up to 2,240 mm

-

Maximum Airflow: 500,000 m³/h

-

Maximum Pressure: 10,000 Pa

-

Temperature Resistance: up to 300°C

Discover more

CBI’s industrial fans are designed for high efficiency, reliability, and reduced noise emissions, making them ideal for industrial installations requiring silent axial and centrifugal fans.

Calculating soundproofing and insulation of a quiet industrial fan

If soundproofing or insulation needs to be calculated, it is always recommended to express noise levels in dBA of sound power LWA per octave band. Upon request, CBI’s fans can be supplied with insulated casings featuring two types of coating.

-

Types of Insulation for Noise Reduction

-

-

Type 1 Insulation: 100 mm thick rock wool with a density of 100 kg/m³, protected by a galvanized steel or aluminum sheet (0.8–1mm thick). This provides moderate acoustic attenuation.

-

Type 2 Insulation: 100 mm thick rock wool combined with a 2.5mm thick EPDM layer (5 kg/m²), also protected by a galvanized steel or aluminum sheet. This offers superior noise reduction.

-

-

Impact of Installation and Environmental Conditions

-

-

Sound attenuation values can change depending on installation type and operating conditions.

-

Fans with both inlet and outlet ducts (without vibration isolators) exhibit different noise levels compared to those with open intakes.

-

-

Other Considerations for Noise Management

-

-

Increased distance from the noise source significantly reduces perceived sound levels.

-

Placement within a reverberant environment can alter noise values significantly.

-

Additional elements, such as calibration dampers and flow regulators, can impact overall noise emissions.

-

Installation Considerations for Noise Reduction

In addition to selecting an insulated industrial fan, proper installation is essential for minimizing noise. Here are key recommendations:

-

Use Anti-Vibration Mounts – Reduce structure-borne noise by installing rubber or spring isolators.

-

Ensure Proper Distance from Noise-Sensitive Areas – Noise reduction depends on both direct distance and environmental factors.

-

Monitor the Operating Conditions – Deviations from optimal operating points can affect noise emissions by up to 3 dBA.

The Importance of Insulation for Noise Reduction

Choosing the right insulated industrial fan ensures a quieter, safer, and more efficient working environment. CBI Group’s range of insulated axial and centrifugal fans offers advanced noise-dampening solutions, making them ideal for industrial applications that demand both performance and low noise levels.

For those looking to invest in high-quality insulated fans, CBI’s products provide industry-leading soundproofing and reliability

Contact us