OUR PRODUCTS

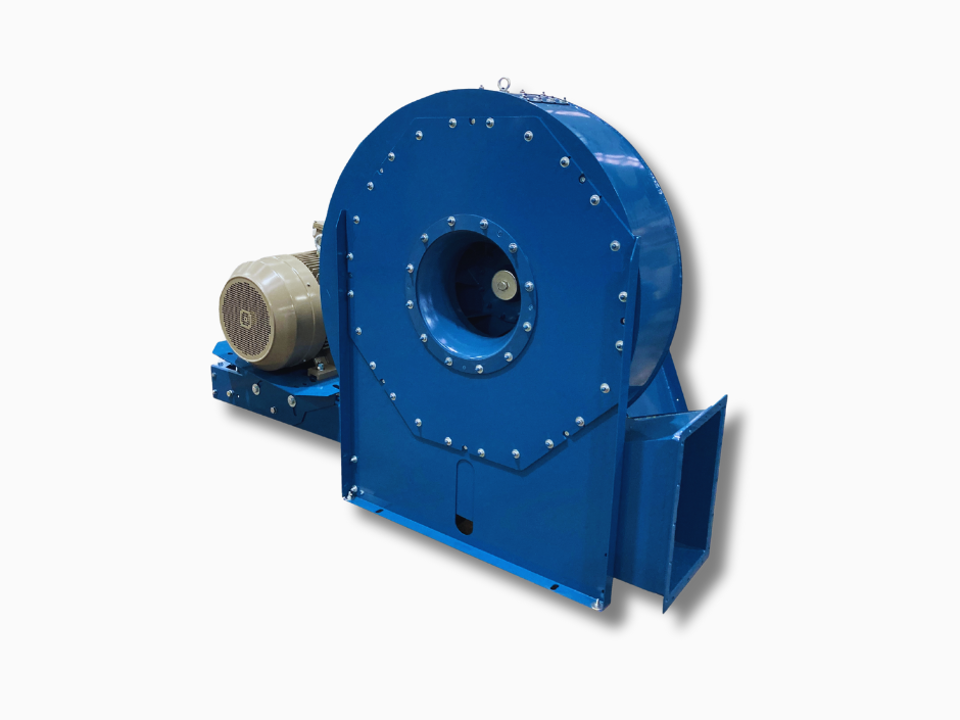

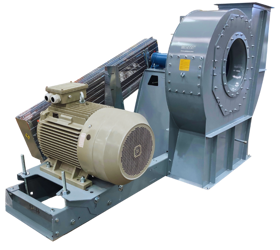

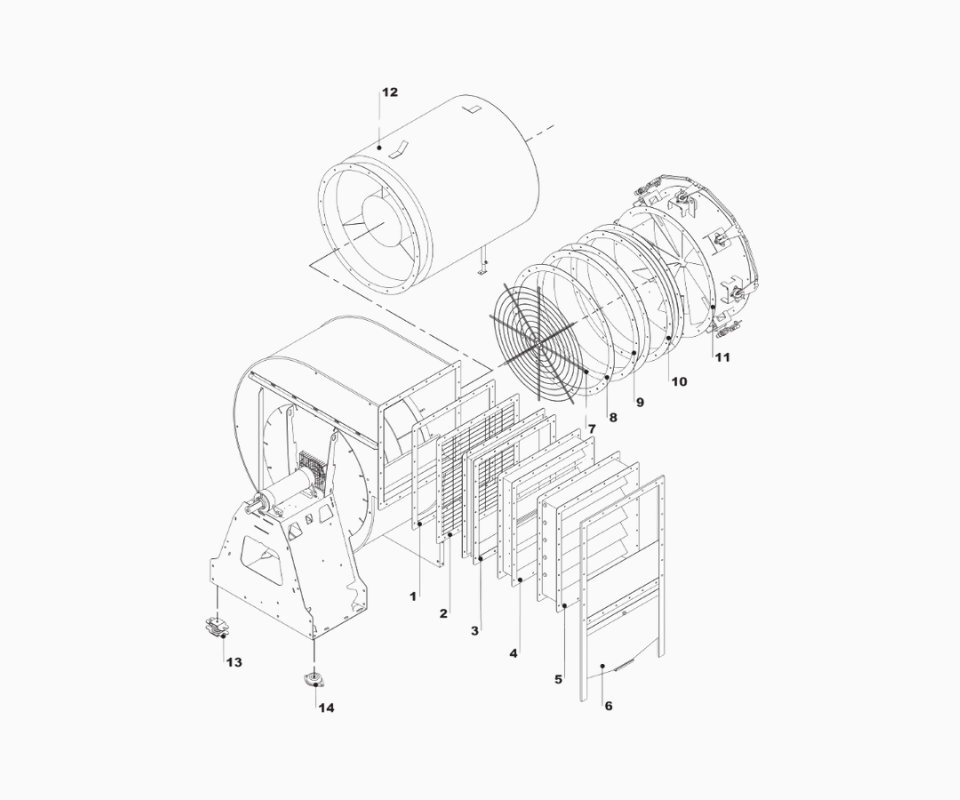

K series

The “K” series of centrifugal fans has been specifically designed to convey air, gases with dust, grainy materials and long fibers.

The careful design of the auger and the three different types of impeller that can be mounted has allowed the creation of this series of fans that have a great versatility of use with the maximum efficiency found in their field of use. Sturdy construction is one of the main features.

Technical specifications

- Pressure (max): 9.000 Pa

- Flow rate (max): 350.000 m³/h

- Impeller size: available in 18 sizes with impeller diameters ranging from 400 mm to 2.200 mm

- Blades: backward inclined

- Direct or belt-driven executions

- Processing clean or dusty air

- In conformity with ERP standard

Special execution:

- Stainless Steel AISI

- ATEX compliant

- Polypropilene

- Gastight Execution

- Insulated execution

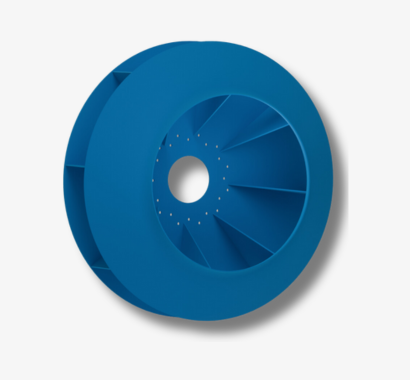

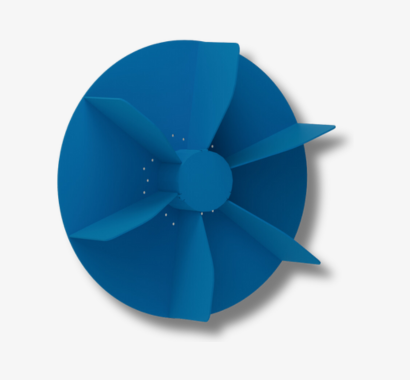

Impeller model

KB Impeller

This type of impeller has an excellent efficiency and is particularly suitable for conveying clean air, fumes and gases or those containing low concentrations of dust.

The KB impeller has 11 backward inclined blades welded to an aerodynamic cone and to the rear disc.

KR Impeller

This type of impeller is used to convey air or gases containing dry granular materials, powders and other materials such as shavings, sawdust, etc.

The KR impeller has 8 radial blades welded to an aerodynamic profile cone and to the rear disc.

KF Impeller

This impeller is particularly designed for the transport of materials with strong adherence, heavy or abrasive or filamentary.

The KF impeller has 6 radial blades welded to the rear disc and to a special hub.

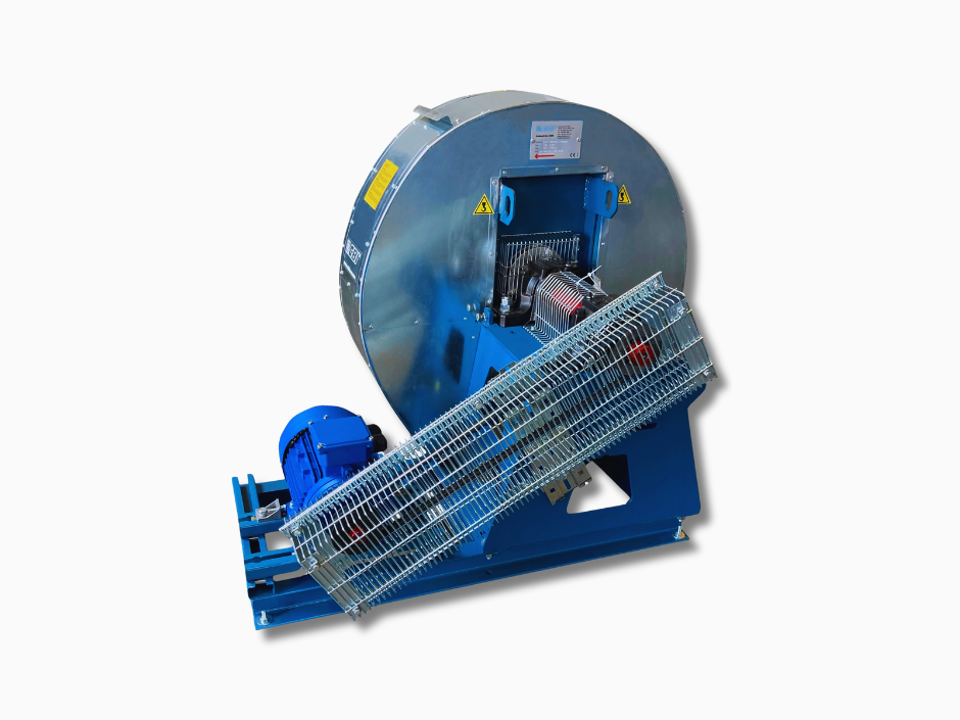

Accessories

- Outlet counterflange

- Outlet screen

- Outlet flexible connection

- Outlet damper

- Gravity damper

- Coulisse damper

- Inlet screen

- Inlet counterflange

- Outlet flexible connection

- Inlet spigot

- Inlet Vane Control

- Inlet Silencer

- Spring isolators

- Rubber isolators