OUR PRODUCTS

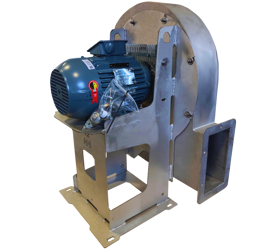

N series

The N series centrifugal fans directly coupled to the electric motor are the result of our extensive experience in the design and construction of fluid-carrying systems.

Careful planning has allowed us to create these fans, whose main features are versatility and reliability.

The fans in this series are used in a wide range of industrial ventilation systems requiring a limited flow with a fair amount of pressure.

Technical specifications

- Pressure (max): 8.000 Pa

- Flow rate (max): 12.000 m³/h

- Housing: in steel sheet with Pittsburgh seaming

- Series N fans can be equipped with three types of impellers depending on the fluid they are intended to convey.

Special execution:

- Impeller in AISI 304

- All parts in contact with the fluid in Aisi 304

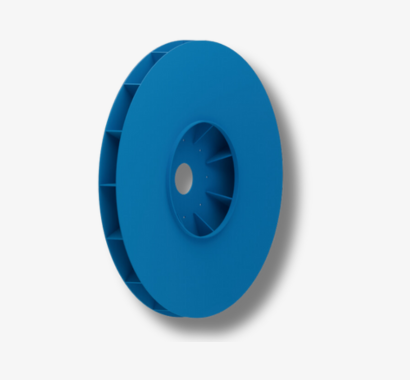

Impeller model

NC Impeller

This type of impeller has 12 backward curved blades welded to an aerodynamic cone and to the rear disk.

It is particularly suited to conveying clean air and fluids.

The NC series is produced in 5 sizes with impellers ranging from 400 to 630 mm in diameter.

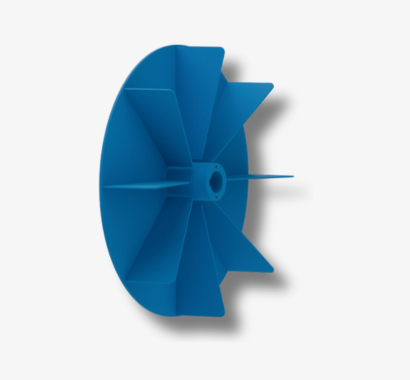

NR Impeller

This type of impeller has 12 radial blades welded to an aerodynamic cone and to the rear disk.

It is particularly suited to conveying air and fluids containing small quantities of dry dust.

The NR series is produced in 5 sizes with impellers ranging from 400 to 630 mm in diameter.

NF Impeller

This type of impeller has 8 radial blades welded to the rear disk. It is particularly suited for conveying fluids containing small quantities of fibres or shavings.

The NF series is produced in 3 sizes with impellers ranging from 400 to 500 mm in diameter.

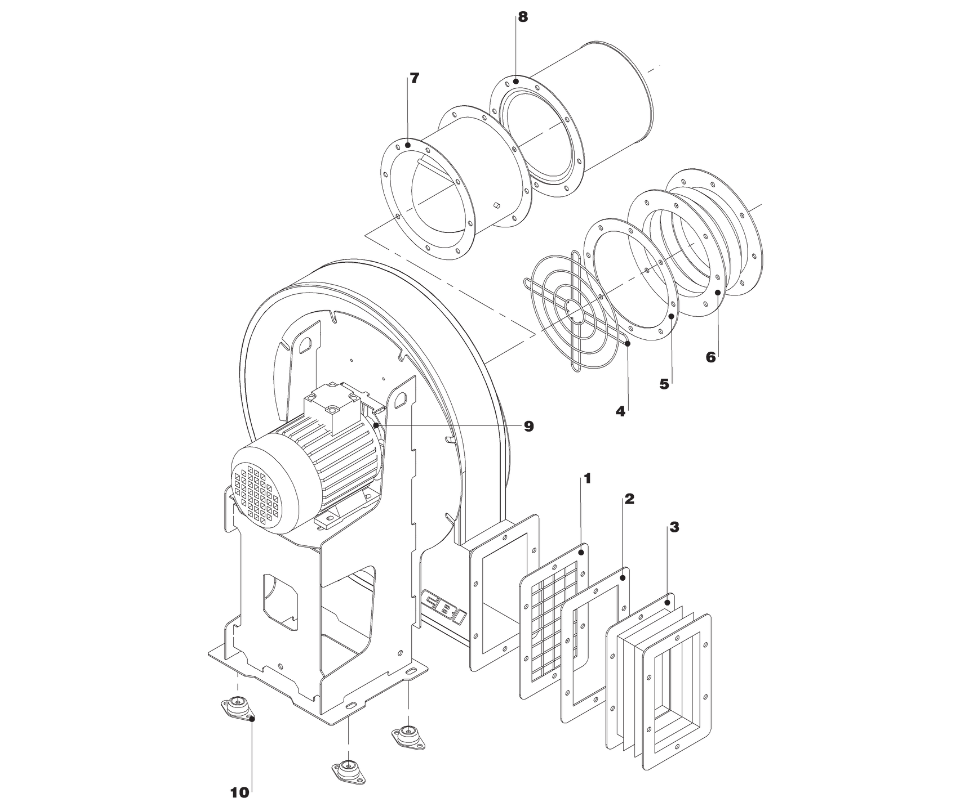

Accessories

- Outlet counterflange

- Outlet screen

- Outlet flexible connection

- Outlet damper

- Gravity damper

- Coulisse damper

- Inlet screen

- Inlet counterflange

- Outlet flexible connection

- Inlet spigot

- Inlet Vane Control

- Inlet Silencer

- Spring isolators

- Rubber isolators