- Homepage

- Technical Insights

- Axial Fans: Working Principle, Characteristics, Uses, and Efficiency

Axial Fans: Working Principle, Characteristics, Uses, and Efficiency

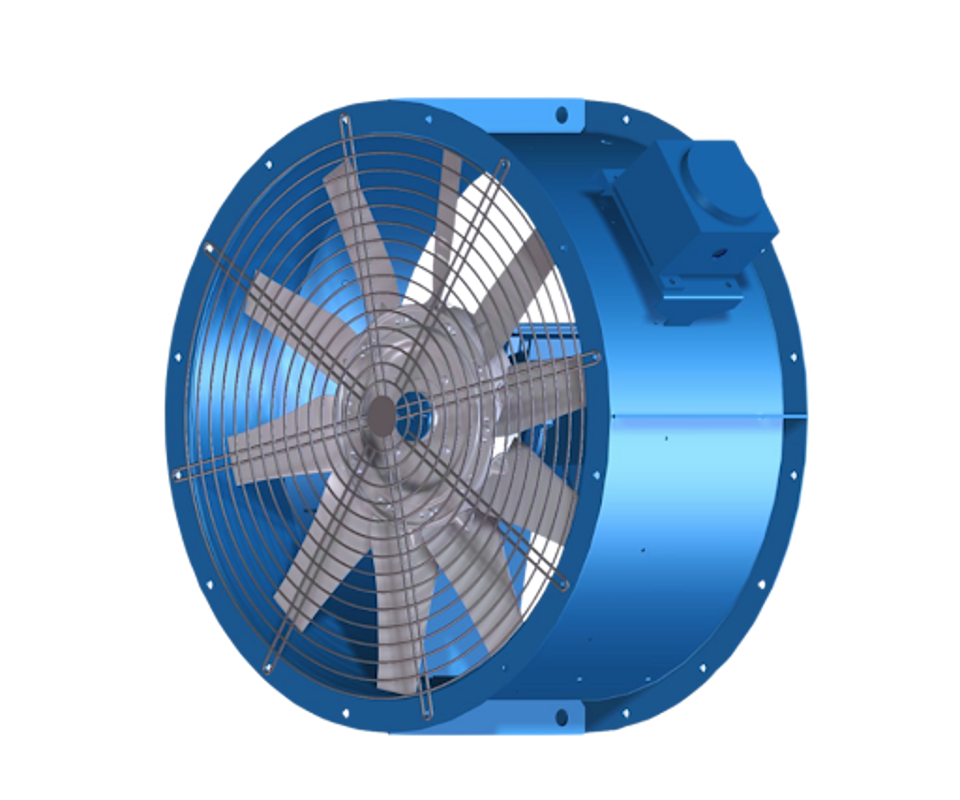

Axial fans are an essential component in various industrial and commercial applications, providing efficient airflow and ventilation solutions. Whether used in HVAC systems, industrial cooling, or tunnel ventilation, axial fans offer high-volume airflow with low pressure, making them indispensable in many sectors. This guide explores the working principles, applications, and technical aspects of axial fans, providing valuable insights for engineers, manufacturers, and industry professionals.

What is an Axial Fan? Definition and Overview

An axial fan is a type of mechanical fan that moves air parallel to its axis. It is commonly used in ventilation, cooling, and air circulation applications. The airflow direction remains linear, making axial fans highly effective for applications requiring high airflow at low pressure. Every model CBI series is designed to meet the most diverse installation and operational needs, ensuring the highest performance and utmost durability.

Key Characteristics of Axial Fans

Axial fans exhibit the following features:

-

Linear airflow: moves air parallel to the fan's axis.

-

High flow, low pressure: ideal for large-volume airflow with minimal pressure.

-

Compact design: requires less space compared to centrifugal fans.

-

Energy efficiency: uses less power for moving large air volumes.

-

Multiple blade configurations: mono-directional or reversible blades that are available with airfoil profiles.

Moreover, the modular design enables various assembly configurations tailored to the technical requirements of each application. This flexibility allows every CBI Group industrial axial fan to be customized for optimal air management, ensuring superior system performance.

Axial Fan Uses: Applications Across Industries

Industrial Ventilation

Used in factories and manufacturing plants to circulate air, remove fumes, and enhance worker safety. Proper ventilation is critical in industrial settings to prevent air stagnation, control temperature, and improve air quality.

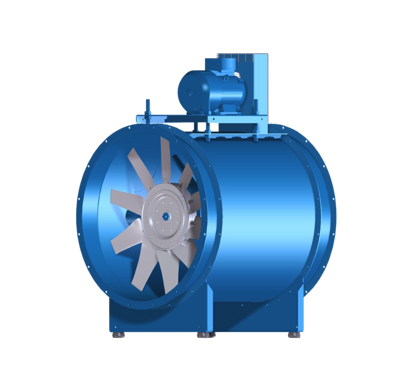

Industrial Axial Fans

Cooling Systems

Commonly used in industrial cooling, and generator ventilation. These fans prevent overheating in sensitive machinery and ensure operational stability by maintaining a controlled temperature.

Discover more

Tunnel & Metro Ventilation

Axial fans are essential for maintaining air quality in underground transportation systems such as subways and road tunnels. They help evacuate exhaust gases and, in case of fire, enable rapid smoke extraction. Compliance with strict safety regulations is necessary, as tunnel ventilation fans must operate at extreme temperatures, up to 400°C for 2 hours, ensuring emergency preparedness.

T&M - Tunnel & Metro Solutions

Nuclear Power Plants

Axial fans in nuclear facilities are designed to handle highly controlled environments. They are used for both ventilation and the extraction of hazardous gases, ensuring safe air circulation in critical areas. These fans must comply with stringent seismic and safety regulations to withstand operational challenges in nuclear plants.

NS - Nuclear SolutionsAxial Fan Working Principle

Axial fans operate by generating airflow along their axis using rotating blades. As the impeller rotates, it creates a pressure difference, drawing air in and propelling it forward. The efficiency of this process depends on:

-

Blade design and angle.

-

Motor speed and power.

-

External resistance affecting airflow.

Axial Fan Efficiency and Performance Curve

Axial fan efficiency is determined by its ability to convert electrical energy into airflow with minimal losses. The performance curve helps in understanding:

-

Flow Rate (m³/h): Volume of air moved per hour.

-

Static Pressure (Pa): Resistance faced by the airflow.

-

Efficiency Levels (%): Power utilization effectiveness.

Types of Axial Fans and Technical Specifications

CBI Group manufactures a variety of axial fans, each with unique specifications. Below is a comparison of available models:

|

Model |

Blade Type |

Max Flow Rate (m³/h) |

Max Pressure (Pa) |

Application |

|

GAT Series |

Airfoil |

50,000 |

600 |

General Ventilation |

|

GAV Series |

Airfoil |

300,000 |

1,000 |

HVAC, Cooling |

|

GAX Series |

Airfoil |

300,000 |

1,000 |

Industrial Use |

|

EFA Series |

Airfoil |

480,000 |

1,800 |

Industrial Use |

|

AXL Series |

Airfoil |

830,000 |

5,000 |

Metro & Tunnel |

Explore our industrial axial fans

Can Axial Fans be Used in Series?

Yes, axial fans in series can be used to increase total pressure while maintaining the same airflow rate. This configuration is beneficial in applications where increased pressure is required but space constraints limit the use of larger fans.

CBI Group: Leading Axial Fan Manufacturers

As one of the top axial fan manufacturers, CBI Group provides high-quality ventilation solutions for industrial applications worldwide.

Why choose CBI Group?

-

Unmatched reliability: we have been in continuous operation since 1980, proving our long-term durability.

-

Innovative engineering: our company leverages advanced automated design systems, allowing for fast, error-free customization of tailor-made ventilation solutions.

-

Comprehensive 360° service: we are one of the few companies offering a full-service approach, from design and manufacturing to installation and maintenance.

-

Efficient repairs & maintenance: our automated repair systems ensure faster turnaround times with minimized errors.

-

Global reach: with the capability to intervene on-site anywhere in the world, we provide expert support wherever it is needed.

Contact us