- Homepage

- Productions

- Cement Fan

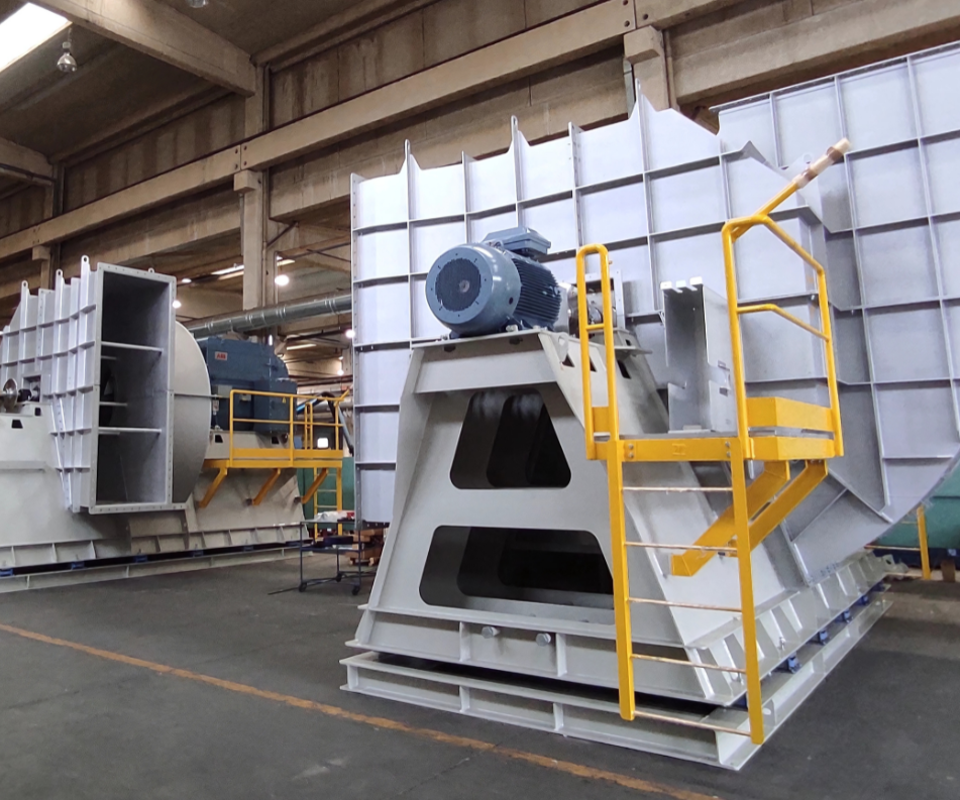

Cement Fan

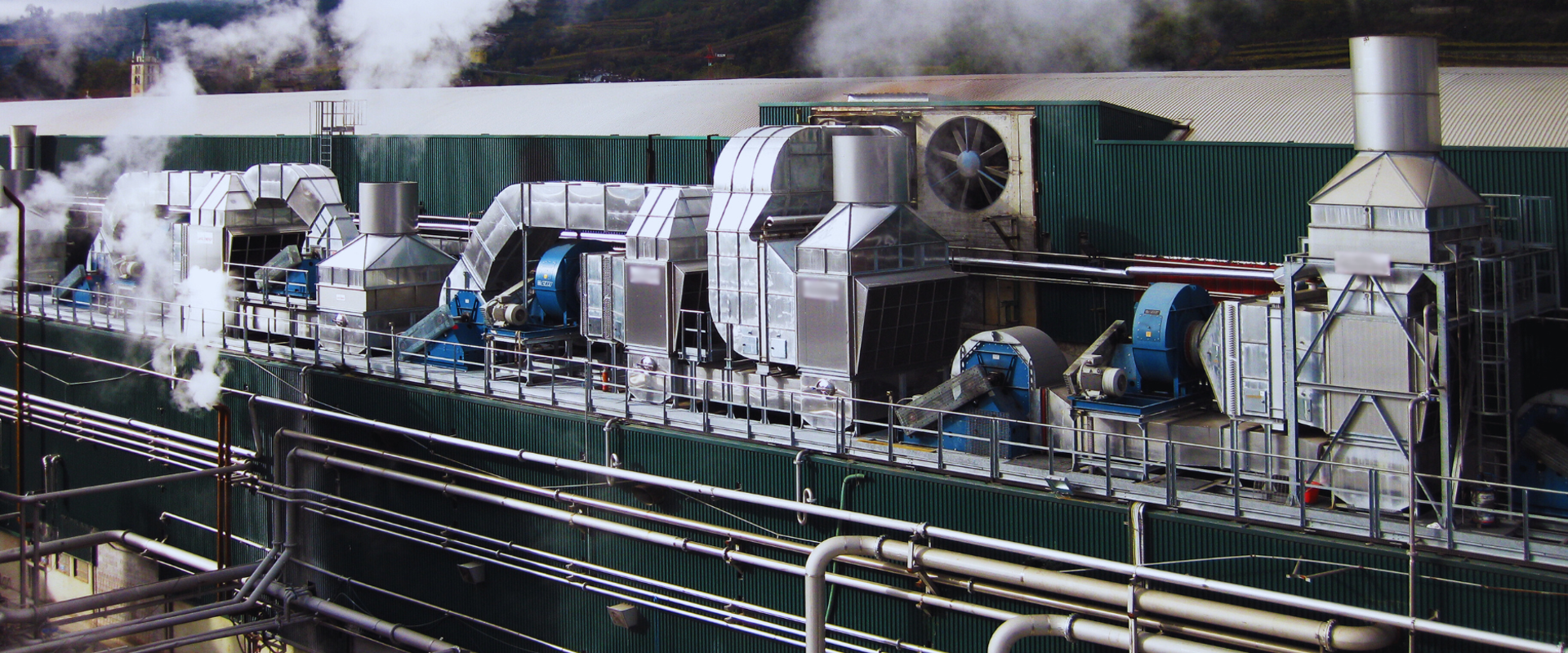

Industrial cement fans for: rotary kiln cooling, dedusting, transport and homogenization of raw materials, drying.

Maintaining a consistent quality of cement depends on precise control of gas flow, ensuring your fans operate with the right speed and efficiency. This applies to processes such as the preheater, clinker cooling, and the handling of gases generated during cement production.

Our heavy-duty fans offer exceptional performance, unlocking significant energy savings through optimized fan motor speed management.

Precise gas flow, controlled speed, and efficiency – every detail is crucial for ensuring the best fan results.

Want more information?

Contact us

Types of Fans Used in Cement Plants

When it comes to cement production, ensuring optimal performance in demanding environments is essential. For applications such as rotary kilns, clinker coolers, and dedusting, CBI's heavy-duty fans deliver unmatched reliability and efficiency. Our fans are engineered to handle extreme conditions.

Series like the S Series, M Series, and X Series offer high-performance solutions for precise gas flow control and energy savings, with static parts (casing, base supports, motor) made from robust steel sheet metal, welded and reinforced with ribs and profiles:

-

The S Series is designed for efficient motor speed management, ensuring smooth operation even in the most challenging conditions. It offers two configurations: with transmission or direct coupling to the electric motor for fixed rotational speed.

-

The M Series provides exceptional durability for heavy-duty tasks and offers two configurations: transmission or direct coupling to the electric motor, with adjustable impeller options for six different performance levels.

-

For X Series is engineered for applications requiring extra robustness and stability and comes in two configurations: transmission or direct coupling to the electric motor, which provides fixed rotational speed. In the direct coupling version, performance can be optimized by adjusting the impeller, offering six different performance options.

All the systems are built to withstand temperatures up to 300 °C, ensuring durability in harsh environments.

For more standard needs, additional fan series offer tailored solutions:

-

The CH Series includes larger models suited for industrial applications. The main construction quality of the CH fans is their ability to ensure high air flow rates while maintaining a moderate pressure level, delivering high efficiency and low noise levels.

-

The HD Series offers high-pressure solutions, designed to meet the heavy-duty requirements of cement plants.

Each series have options for:

-

ATEX compliance for hazardous environments.

-

Construction in AISI 304, AISI 316, AISI 310 stainless steel and other special steels suitable for use in the presence of aggressive agents or for food or high temperatures.

-

Insulated executions to reduce noise and heat.

-

Gastight models for corrosive gases or environments with high dust content.

Why Installers Prefer CBI Fans

CBI fans offer ease of integration into existing systems and delivering significant long-term performance benefits. Our high-efficiency fans reduce maintenance costs and optimize energy consumption, ensuring a smoother installation process and lower operational expenses for your clients.

With a broad range of customizations available, CBI ensures that your systems will meet every specific demand of cement production, from handling harsh environmental conditions to maximizing energy efficiency.

Are you an installer and want more information?

Typical Cement Fans Applications

-

Rotary kiln cooling — Effective fan operation is essential for cooling the rotary kiln, ensuring the cement is produced at optimal temperatures while maintaining energy efficiency and prolonging equipment life.

-

Dedusting — Fans play a critical role in dedusting processes, ensuring dust particles are efficiently removed from the air, improving air quality and maintaining the cleanliness of the production environment.

-

Transport and homogenization of raw materials — Fans are vital for the smooth transport and even homogenization of raw materials, ensuring consistency in the mix and enhancing the overall quality of the cement.

-

Drying — In the drying stage, precise fan control ensures the even removal of moisture from raw materials, optimizing energy use and preparing the materials for subsequent processing steps.

If you need more information or a free consultation, do not esistate to contact us!

Contact us

Custom tailor made

We are able to study and provide customized solutions for all specific needs.

Contact us for more information, you will speak directly with one of our experts.

Contact us for more informations

Divisions

The CBI Divisions specialize in offering specific and customized products and services. Learn more about our Divisions.

Heavy Duty

The Heavy Duty division is focused on robust, high-strength solutions, designed to tackle the most demanding applications.

Find out more

Industrial

The Industrial division, thanks to a wide range of standard products, is focused on providing you with the best solutions for your industrial processes.

Find out more

Engineering

The Engineering division, through a know-how gained in over 60 years, is able to design and produce customized industrial centrigufal and axial fans for any of your needs.

Find out more

Infrastructure

The Infrastructure division is focused on providing you with the best solutions for the specific needs of the infrastructure world.

Find out more

Service, Spares & Maintenance

The Service division is focused on providing qualified assistance services for the installation and start-up of industrial fans, revamping services, reverse engineering services, testing and diagnosis activities.

It also guarantees the supply of spare parts for any industrial fan.

Find out more

Research & Development

The Research & Development division is focused on the constant search for optimized performance, the study of product evolutions and the industrialization of new solutions.

Our team of engineers uses the most advanced FEM, CFD technologies and modern testing rooms.

Find out more